Carpenter in Las Vegas

In Las Vegas, homeowners need skilled carpenters for renovations, upgrades, and repairs adapted to desert conditions, including specialized carpentry for bathroom remodeling projects. The Hanson Company has served Las Vegas since January 2000, bringing over 25 years of hands-on construction experience to every project. Owner Bryan Hanson worked in every aspect of the trade from craftsman to superintendent, gaining expertise in all major carpentry disciplines. Our team specializes in carpentry that withstands Nevada's unique conditions including extreme temperature swings from 20°F to 115°F, intense UV exposure, low humidity ranging from 10-30%, and rapid material expansion and contraction. Our OSHA certified craftsmen follow occupational safety and health standards on all projects. Many team members completed apprenticeships and receive ongoing training in construction methods adapted to Las Vegas conditions. Call The Hanson Company at +17027629788 to discuss your carpentry project.

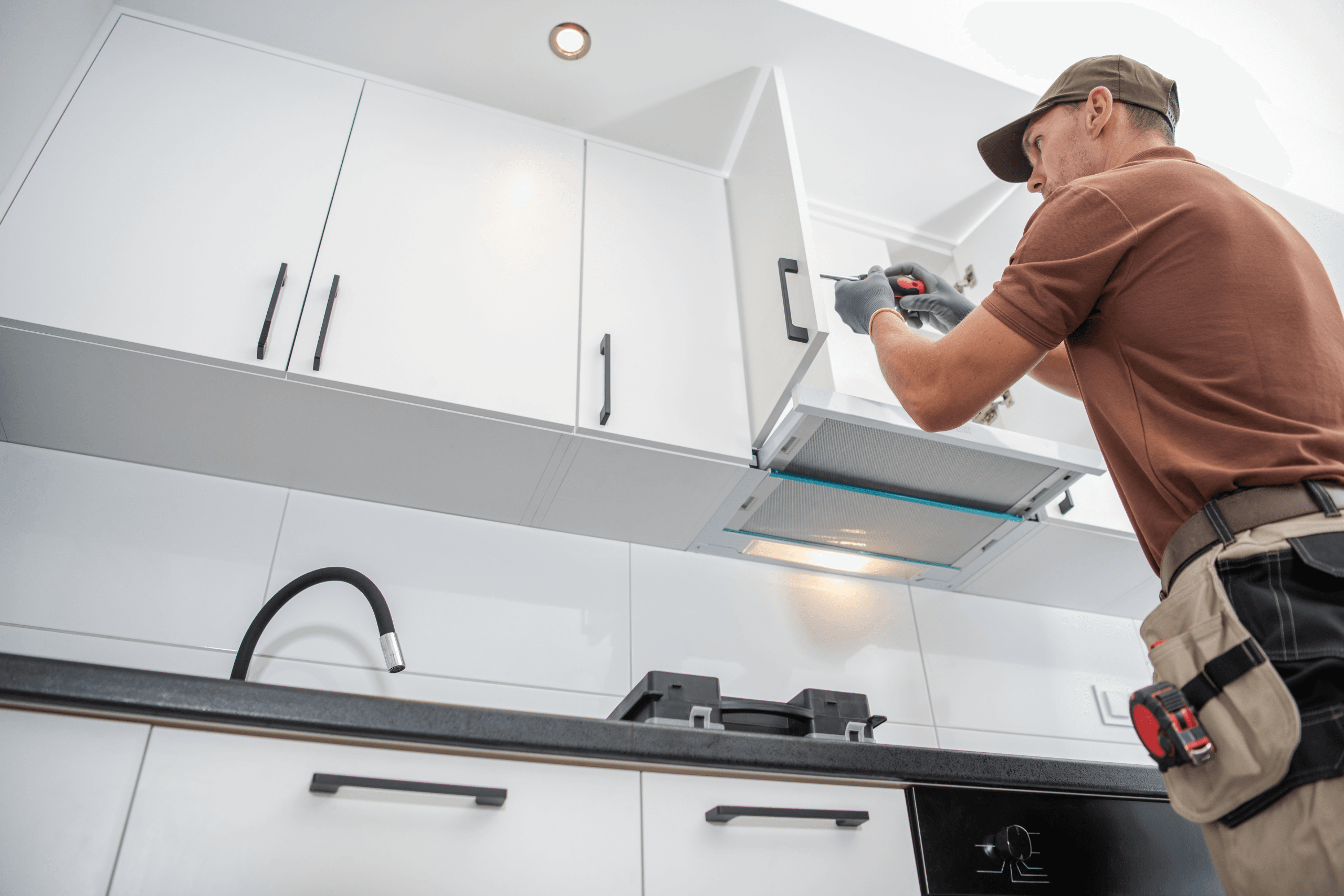

Cabinet Installation in Las Vegas

Homeowners updating kitchens, bathrooms, or laundry rooms benefit from cabinet installation designed for desert conditions. Professional cabinetry work requires understanding joinery techniques and proper tool use adapted to extreme temperatures and low humidity. Installation ensures cabinets fit level and secure while accounting for foundation settling common in Las Vegas homes, especially during the first few years after construction. Quality cabinet work involves measuring and cutting lumber to exact dimensions while accounting for minimal moisture content in desert air. Understanding how materials expand and contract in extreme temperature swings prevents future problems with doors, drawers, and cabinet alignment.

Our installation process includes removing old cabinets if needed, accounting for floor-level variations common in Las Vegas slab foundations, leveling and shimming base units using heat-resistant materials, and securing cabinets to studs with appropriate fasteners. We use adhesive rated for high temperatures and low humidity, which differs from products used in coastal climates. Cabinet boxes may include furniture-grade joinery methods for durability under temperature stress. Cabinet installation is especially popular in Henderson and Summerlin homes during kitchen and bath remodels. Older Las Vegas homes built during the 1980s and 1990s often need cabinet updates as original builder-grade units show wear from decades of heat exposure. Our team applies information from over 25 years of local cabinetry experience to each project.

Bathroom Vanity Installation in Las Vegas

Homeowners remodeling bathrooms or replacing old vanities choose professional vanity installation for updated style and function while ensuring stability in Las Vegas homes where foundation settling is common. Bathroom work requires understanding moisture-resistant materials that also handle extreme temperature swings and low ambient humidity. The low humidity in Las Vegas causes different material behavior than coastal climates, requiring specific product selection and installation techniques. Our installation process begins with removing the existing vanity and inspecting plumbing connections. We check for foundation movement or settling, which is common in Las Vegas homes, especially those built during the rapid construction boom of the 1990s and 2000s.

We secure the cabinet to studs using anchors rated for desert conditions, install the countertop with proper sealing against low humidity, and apply flexible caulking that withstands temperature changes without cracking. The trade requires understanding drywall repair, plaster work when needed in older homes, and proper adhesive selection for wet areas in dry climates. Metal brackets and concrete anchors may secure heavy vanities to block surfaces common in Las Vegas construction. Bathroom vanity installation is a frequent upgrade in older homes throughout Paradise and Spring Valley built during Las Vegas's rapid growth periods. Our skilled crew handles all aspects of vanity work with proper training and occupational safety practices developed specifically for Las Vegas construction challenges.

Custom Cabinetry in Las Vegas

Homeowners wanting built-in storage solutions or unique designs benefit from custom cabinetry designed specifically for their space and Las Vegas conditions. Custom cabinets fit exact spaces and match your style while accounting for foundation settling, temperature extremes, and low humidity unique to desert construction. Creating custom pieces requires expertise in joinery, material selection, and construction techniques adapted to desert conditions. Understanding different lumber types, grain patterns, and how materials behave in low humidity factors into every decision. Our process involves detailed design work that accounts for common Las Vegas home features, selecting materials proven in Nevada climate, creating detailed drawings with expansion allowances, acclimating lumber to local humidity levels before cutting, building using techniques that handle temperature stress, and applying climate-appropriate finishing with stains and paints rated for UV exposure and heat.

Advanced education and apprenticeship training prepare craftsmen for this detailed trade work using tools like table saws, routers, planers, and specialized equipment. We sand surfaces smooth then apply stain or paint using products that resist fading and degradation from intense UV exposure. Quality adhesive bonds joints permanently even in extreme heat, maintaining structural integrity through temperature cycling. Custom cabinetry is especially popular in Summerlin for kitchen islands, entertainment centers, and home offices where custom built-ins define spaces in open floor plans. Custom work is also valuable in older Las Vegas homes where non-standard room dimensions require fitted solutions. Information gained through years of experience working in Las Vegas guides material choices and construction methods that last in our unique climate.

Trim Carpentry in Las Vegas

Homeowners finishing remodels or refreshing room appearance rely on trim work to complete their spaces while handling desert climate challenges. Trim covers gaps and adds detail to surfaces, doors, and windows, creating clean lines that accommodate settling and temperature movement common in Las Vegas construction. Finish carpentry requires precision and understanding of molding profiles that handle temperature extremes without warping or separating. Trim work involves cutting angles, coping joints, and installing baseboards, casings, and crown molding using techniques that prevent gaps as materials adjust to indoor climate control versus outdoor heat. Proper technique is especially important in newer Las Vegas construction where settling is common during the first two to three years.

We install baseboards along floor edges, door casings around entryways, window trim, chair rail, crown molding at ceiling lines, and wainscoting. We use miter saws for precise angle cuts, coping saws for inside corners, and nail guns for efficient fastening. Understanding grain patterns and matching species creates professional results that remain stable through years of temperature cycling. Metal nails secure trim without splitting material that may be dryer than lumber in humid climates. We select materials that maintain stability in low humidity and high heat, ensuring trim remains secure and gap-free. Occupational safety includes proper tool handling and personal protective equipment, especially important when working in Las Vegas garages during summer months when temperatures can exceed 140°F. Trim work is needed in both new construction and older homes across Downtown and North Las Vegas. Our crew brings years of finish experience to each project.

Crown Molding Installation in Las Vegas

Homeowners adding elegant details to living rooms, dining rooms, or bedrooms choose crown molding installation to create finished ceiling lines and add visual interest while handling the unique challenges of Las Vegas homes. Crown molding increases home value and appeal, creating architectural character that distinguishes properties in competitive Las Vegas real estate market. Installing crown molding requires understanding ceiling angles, surface conditions, and proper joinery techniques adapted to homes where foundation settling and temperature movement create challenges. Calculating compound miter cuts where surfaces meet at corners takes precision, especially in homes where settling has created irregular angles, common in Las Vegas properties over ten years old.

Our process involves measuring room perimeter and calculating materials while adding extra for desert climate adjustment, marking stud locations which is critical since wall construction varies by builder and era, cutting molding at compound angles, test-fitting pieces, applying construction adhesive rated for high temperatures, nailing molding to studs and ceiling joists, filling nail holes and caulking gaps with flexible materials, and painting using UV-resistant products for rooms with sun exposure. Crown molding creates visual height in rooms, particularly valuable in Las Vegas homes with standard eight-foot ceilings. The molding hides gaps that commonly appear from settling and temperature movement in desert construction. Adhesive supplements nails using products that remain flexible through temperature changes. Professionals with apprenticeship training handle complex layouts including vaulted ceilings and transitions. Crown molding is a common upgrade in Green Valley and Henderson master suites and formal spaces, established neighborhoods where original builder-grade trim is being replaced with upgraded profiles.

Door Installation in Las Vegas

Homeowners replacing damaged doors or upgrading interior and exterior entries need professional door installation designed for desert conditions. New doors improve security, insulation, and style while dramatically reducing energy costs in Las Vegas's extreme climate where cooling expenses dominate utility bills six to nine months yearly. Proper hanging prevents sticking and gaps while accounting for material movement with temperature changes ranging from winter lows around 20°F to summer highs reaching 115°F or higher. Door work requires understanding frame construction, hardware installation, and building codes specific to desert climate and energy requirements.

We install entry doors made from steel, fiberglass, or solid core materials with high insulation values, interior passage doors, French doors with energy-efficient glazing, sliding patio doors with proper weather sealing, pocket doors, bifold closet doors, and storm doors with screen options. Our installation process includes removing the old door and hardware, inspecting and repairing the frame if needed, checking for square and level, installing hinges, hanging and testing the door, planing or trimming edges accounting for seasonal expansion, installing locksets and strike plates, adding weather stripping for exterior doors, adjusting threshold height, and testing operation with final adjustments. Proper installation accounts for material movement in Las Vegas heat where doors expand during summer and ensures smooth operation year-round. Steel or metal reinforcement strengthens exterior frames for security, especially important where direct sun exposure weakens untreated materials over time through UV degradation. We recommend specific R-values and materials proven to reduce cooling costs, typically suggesting steel or fiberglass over wood for exterior applications. Door installation is especially popular in Spring Valley home updates where original doors from the 1980s and 1990s with single-pane glass and poor weather sealing lose tremendous efficiency. Upgrading to modern insulated doors can reduce cooling costs by fifteen to twenty-five percent in these older homes.

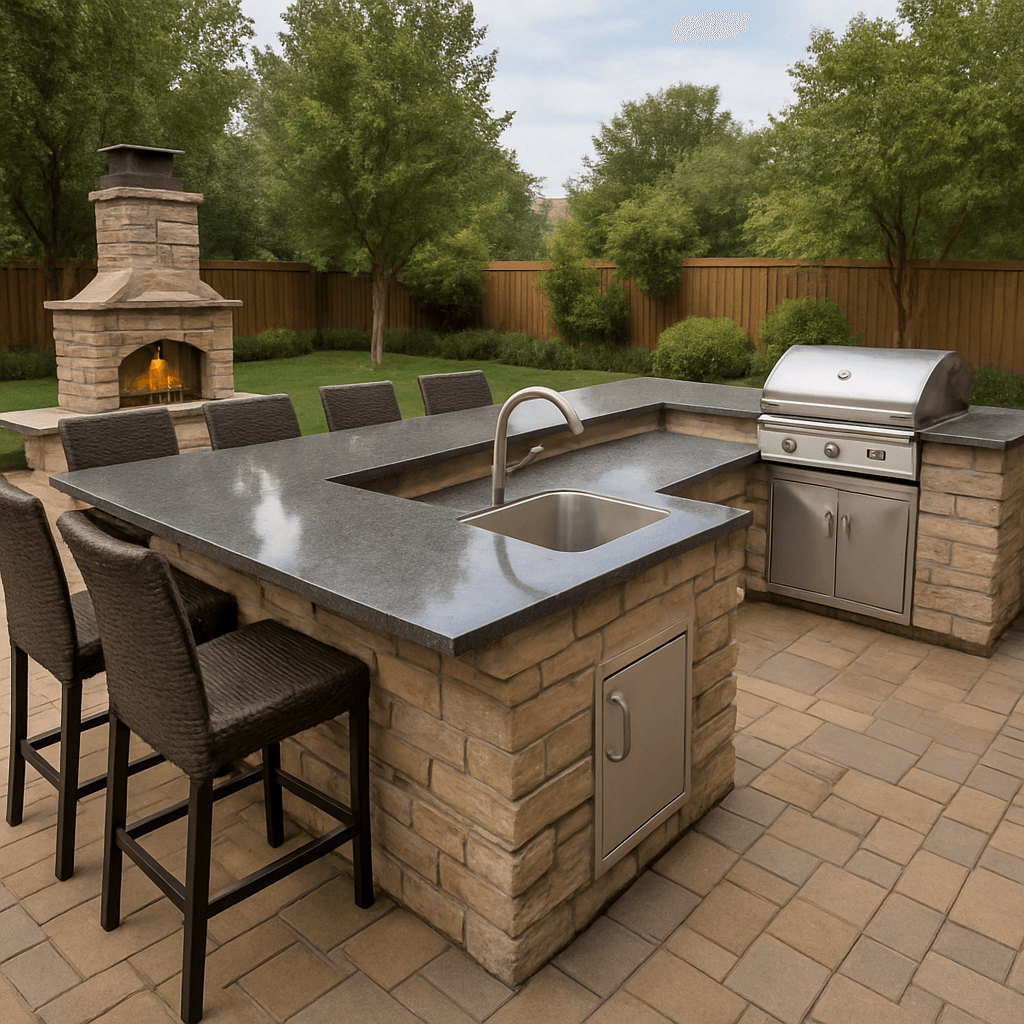

Deck Construction in Las Vegas

Homeowners expanding outdoor living space for entertaining or relaxation invest in deck construction designed for year-round desert use. Custom decks create usable outdoor areas that withstand intense UV exposure, extreme temperatures, and low humidity while providing valuable additional living space in the mild Las Vegas climate that enables outdoor use eight to nine months yearly. Deck design must consider shade structures essential for summer use during days reaching 115°F or higher, material selection for UV resistance and heat tolerance, orientation to minimize afternoon sun exposure, access from main living areas, local building codes and HOA requirements, desert landscaping integration, and year-round usability. We work with pressure-treated lumber rated for low humidity conditions, composite materials with UV inhibitors that prevent fading, or tropical hardwoods like ipe and tigerwood proven to perform in extreme sun exposure.

Our construction process includes planning and obtaining permits while designing the deck accounting for Las Vegas sun angles, site preparation in desert soil conditions, pouring concrete footings at appropriate depths, setting and bracing support posts using corrosion-resistant hardware, installing beams and joists with heat expansion allowances, laying deck boards using fasteners rated for temperature extremes, building railing systems using materials that resist sun damage, constructing stairs accounting for settling, and applying UV-protective stain or sealant. Steel connectors join lumber at key structural points using hardware that remains strong through temperature cycling and UV exposure. Metal flashing protects materials from rare but intense monsoon moisture. Safety standards guide railing height at minimum thirty-six inches, stair dimensions, and structural integrity. Personal protective equipment includes gloves when handling pressure-treated lumber and sun protection during summer installations. Deck construction has especially high demand in Summerlin and Henderson backyards for year-round outdoor use. These master-planned communities feature properties where outdoor living spaces significantly increase property value. Las Vegas residents utilize outdoor spaces eight to nine months yearly, making quality deck construction a worthwhile investment.

Shelving Installation in Las Vegas

Homeowners needing storage in closets, garages, pantries, or offices benefit from shelving installation designed for desert conditions. Custom shelving maximizes space and organizes belongings while handling Las Vegas climate challenges including extreme temperatures in garages that can reach 140°F during summer months. Installing shelving requires understanding construction, weight distribution, and appropriate hardware selection for desert conditions. We locate studs noting that spacing can vary in Las Vegas homes built during different eras, choose proper anchors for drywall or plaster, and calculate shelf span based on intended load and temperature stress. The work involves cutting lumber or sheet materials to size, applying edge treatments that resist heat, and mounting with brackets or cleats rated for extreme temperatures.

Shelving applications include garage storage, closet organization systems, pantry and kitchen storage, home office bookcases, laundry room shelving, mudroom storage, and display shelving. Material selection considers solid lumber for climate stability, plywood with adhesive that handles temperature cycling, melamine products rated for heat resistance, wire shelving systems which perform excellently in hot garages by allowing air circulation, and metal brackets with powder-coated finishes that resist UV degradation. Metal brackets support heavy loads and resist temperature effects. Concrete surfaces common in Las Vegas garages require special masonry anchors. Occupational safety training covers proper ladder use and tool handling, especially important in hot garage environments during summer. Machine sanders smooth lumber edges before installation. Shelving installation is especially common in Downtown condos and homes with limited storage throughout the valley where custom shelving solutions maximize usable space.

Baseboard Installation in Las Vegas

Homeowners finishing new flooring or repairing damaged baseboards need baseboard installation adapted to desert conditions. Baseboards cover floor edges and protect surfaces from damage while handling foundation settling and temperature movement common in Las Vegas homes, especially during the first three to five years after construction when settling is most pronounced. Installing baseboards involves measuring lengths, cutting trim to fit, coping inside corners for joints that remain tight through temperature changes, and mitering outside corners at precise angles. We use miter saws for accurate angle cuts, coping saws for inside corners, and nail guns for efficient fastening. Understanding how baseboards interact with different floor types including tile which is especially common in Las Vegas homes, hardwood, carpet, or vinyl ensures proper height and reveal.

Baseboards cover expansion gaps between floors and surfaces, protect drywall from impacts, hide imperfections in edges, complete finished appearance, accommodate foundation settling, and add visual weight and style. Our installation process includes measuring room perimeter, marking layout, cutting baseboards to length, coping inside corners, mitering outside corners, nailing baseboards to studs, filling nail holes with putty that withstands temperature changes, applying flexible caulk at top edge that handles temperature movement, and painting using products resistant to UV exposure. Adhesive fills gaps behind baseboards on uneven surfaces using flexible products that handle temperature changes. Metal nails or pneumatic fasteners secure trim to studs without over-tightening which allows slight movement. Sandpaper smooths joints before caulking. Professionals with proper training and apprenticeship education handle complex baseboard layouts around doorways and corners. Baseboard installation is frequently done after tile or hardwood projects in North Las Vegas and Paradise homes, established neighborhoods where flooring upgrades require new baseboard installation

Why Choose The Hanson Company for Las Vegas Carpentry

Bryan Hanson founded The Hanson Company in January 2000, bringing expertise from over 25 years of hands-on construction experience working specifically in Las Vegas and understanding the unique challenges of desert climate building. Bryan has worked in every aspect of construction from skilled craftsman to superintendent, gaining expertise in all major trades. He runs the business alongside his two sons, blending deep industry understanding with strong family values. Bryan’s keen eye for detail ensures every project accounts for Las Vegas’s unique challenges including extreme temperature swings from 20°F to 115°F, intense UV exposure, low humidity ranging from ten to thirty percent, and foundation settling common in Nevada’s desert soil conditions.

Our team has operated continuously in Las Vegas since January 2000, giving us over 25 years of experience in this specific market and climate. This provides deep understanding of local building codes and HOA requirements which vary across different Las Vegas communities. We have extensive experience with homes from all Las Vegas building eras from 1950s construction through rapid growth periods of the 1980s, 1990s, and 2000s to current construction. This means we understand neighborhood-specific construction methods in areas including Summerlin, Henderson, Paradise, Spring Valley, Downtown, North Las Vegas, and Green Valley. We have proven material selection expertise for desert climate durability, choosing products and techniques that withstand decades of extreme conditions. We maintain deep understanding of Las Vegas energy efficiency requirements and how proper construction dramatically impacts cooling costs.

We never cut corners on any aspect of carpentry work. Our reputation across Las Vegas is built on reliable, professional service using materials and techniques proven in Nevada’s climate. We place strong emphasis on proper prep work adapted to desert conditions. We maintain clean, organized work environments despite challenges of heat and dust. Attention to detail characterizes every project phase. Results are built to last through extreme temperatures, intense UV exposure, and low humidity conditions. Our crew consists of OSHA certified team members on every job. Long-term employees trained hands-on by owner Bryan Hanson bring consistency and expertise. Crew stability means you work with familiar, trusted professionals. Our team receives ongoing training in construction methods specific to desert climate challenges. Call +17027629788 to discuss your carpentry project with our experienced Las Vegas team.